You face many choices when selecting a cooking equipment set for your commercial kitchen. Operators report high demand for versatile appliances, such as combi ovens, which help maximize space and support diverse menus. As commercial kitchens grow and menu options expand, you need equipment that delivers consistent performance.

Essential Commercial Kitchen Cooking Equipment for Maximizing Efficiency

Commercial Ovens and Ranges

You need commercial ovens and industrial ranges on your kitchen equipment list to handle high-volume cooking. These professional cooking tools deliver consistent heat and support a wide range of menu items. A study by Frontier Energy, Inc. found that upgrading to high-efficiency commercial ovens and restaurant kitchen equipment can cut energy use by up to 40%, helping you with maximizing efficiency and lowering costs.

Deep Fryers and Grills

Deep fryers and grills are essential commercial kitchen cooking equipment for many menus. ENERGY STAR-certified deep fryers are 30-35% more efficient, saving about $460 in gas costs each year. They also offer faster cook times and longer oil life. Always keep Class K fire extinguishers nearby and inspect for safety features to reduce fire risks.

| Metric | Value |

|---|---|

| Energy Efficiency Improvement | 30-35% |

| Annual Gas Cost Savings | $460 |

| Total Gas Cost Savings | $4,800 |

| Additional Benefits | Faster cook times, extended oil life |

Food Processors and Commercial Mixers

Food processors and commercial mixers are professional cooking tools that boost efficiency in food prep supplies. The Waring Commercial WFP14SC, for example, features a heavy-duty motor and leak-proof bowl for high-volume tasks. The VEVOR mixer can handle up to 6.6 lbs of dough at once, making it a staple on any kitchen equipment list.

Slicers and Prep Tools

Slicers and prep tools are food preparation essentials. Proper training and cleaning protocols improve safety and performance, reducing contamination risks. Regular maintenance extends the lifespan of these commercial kitchen tools and keeps your restaurant kitchen equipment running smoothly.

Refrigeration and Freezers

Freezers and refrigeration units are vital commercial kitchen supplies. They keep ingredients fresh and safe. Advanced freezers offer up to 15% energy savings and stable temperatures, which is crucial for food storage necessities. The importance of commercial freezers cannot be overstated—they protect your inventory and support maximizing efficiency.

Prep Surfaces and Worktables

Prep surfaces and worktables are essential kitchen equipment for any commercial operation. Ergonomic designs prevent strain and speed up workflow. Features like undershelves and built-in sinks make food prep supplies more accessible and keep your kitchen equipment list complete.

Storage Solutions and Organization

Organized storage solutions help you maximize space and streamline workflow. Moveable shelves and wire racks increase storage capacity and keep commercial kitchen supplies within reach. Flexible storage lets you adapt to changing needs, supporting efficiency and reducing downtime.

Safety and Sanitation Equipment

Safety and sanitation equipment are critical commercial kitchen tools. Regular staff training, digital checklists, and compliance with HACCP guidelines keep your kitchen safe. Fire suppression systems, proper signage, and scheduled equipment checks help prevent accidents and ensure your restaurant kitchen equipment meets legal standards.

How to Choose the Right Cooking Equipment Set

Assess Menu and Volume Needs

Start your selection process by looking closely at your menu and expected customer volume. Your cooking equipment set should match the variety and quantity of dishes you plan to serve. Begin by writing out your full menu and listing every ingredient. This step helps you identify all the restaurant kitchen equipment you need for food prep and service.

- List every menu item and ingredient.

- Check health codes and customer demand.

- Estimate how many meals you will serve each day.

- Decide what size and quantity of equipment you need.

- Compare suppliers and request quotes.

- Explore financing options like leasing or loans.

- Plan your equipment layout for smooth workflow.

- Make sure all equipment meets safety and sanitation standards.

- Train your staff on proper use and cleaning.

By following these steps, you ensure your commercial kitchen design supports both efficiency and food safety. When you match your equipment to your menu and volume, you avoid bottlenecks and wasted space.

Measure Kitchen Space and Layout

Measure your kitchen carefully before buying any restaurant kitchen equipment. You want to make the most of every inch. Place service and plating stations between the kitchen and dining area to reduce food travel distance. Keep dish return and cleaning zones separate to prevent cross-contamination.

- Choose a layout that fits your restaurant concept and staff size.

- Use galley layouts for small spaces, island layouts for open kitchens, and assembly lines for fast food.

- Arrange workstations to cut down on unnecessary movement.

- Add adjustable-height surfaces and good lighting for staff comfort.

- Use modular equipment and vertical stacking to save space.

Tip: About 70% of new restaurants struggle with limited kitchen space. Multi-functional and compact equipment, like dual-fuel ranges, can boost your cooking output by up to 40% in tight areas. Stacking or wall-mounting appliances can improve efficiency by up to 25%.

If you want to plan for future growth, choose flexible equipment and layouts. Consulting a commercial kitchen design expert can help you balance safety, efficiency, and comfort.

Set a Realistic Budget

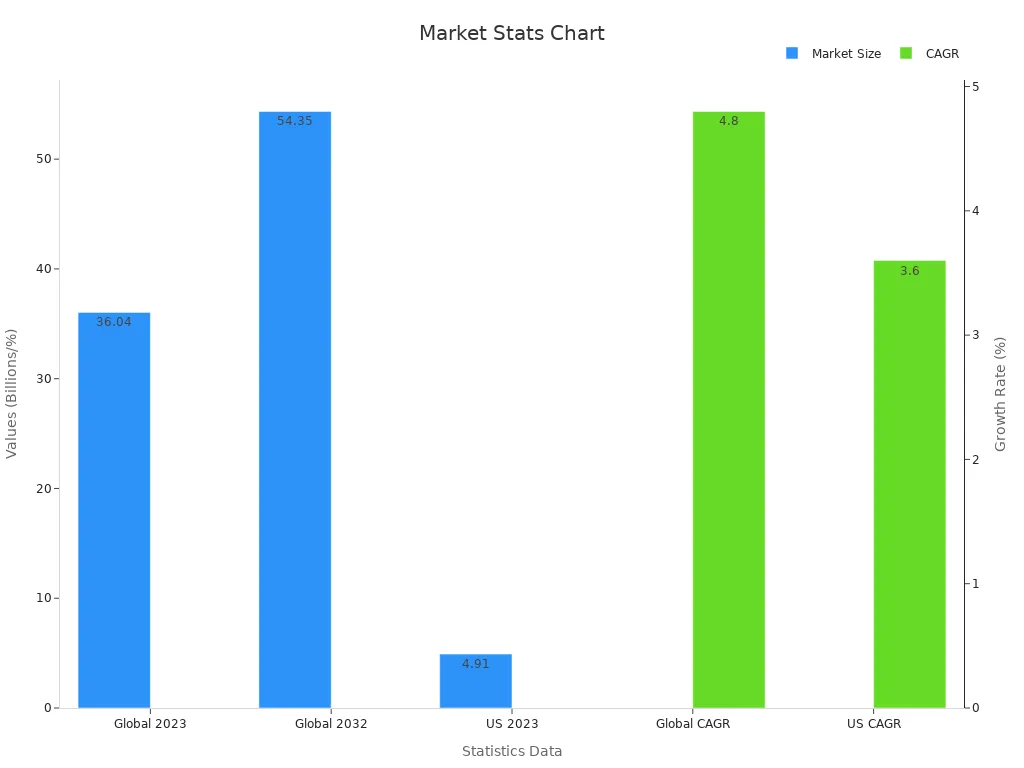

Setting a budget for your cooking equipment set means looking beyond the sticker price. You need to consider ongoing maintenance, repairs, and compliance costs. The market for restaurant kitchen equipment is growing, with new technologies and stricter regulations affecting prices.

| Statistic/Segment | Details/Values |

|---|---|

| Global Market Size (2023) | USD 36.04 billion |

| Projected Global Market Size (2032) | USD 54.35 billion |

| Global CAGR (2024-2032) | 4.8% |

| U.S. Market Size (2023) | USD 4.91 billion |

| Projected U.S. Market Size (2030) | USD 6.48-6.50 billion |

| U.S. CAGR (2024-2030) | 3.6% |

| Segmentation by Type | Ovens, Cooktops and Ranges, Grills, Fryers, Cook-chill Systems, Broilers, Steamers, Others |

| Segmentation by Application | Full-Service Restaurants, Quick-Service Restaurants, Others |

| Key Cost Factors | Maintenance and repair costs, regulatory compliance expenses, impact of advanced technologies |

Remember, advanced restaurant kitchen equipment may cost more upfront but can save you money over time through lower energy use and fewer repairs. Smart and IoT-enabled appliances can improve efficiency but may require a higher initial investment. Always factor in these long-term benefits when planning your budget.

Prioritize Energy Efficiency and Durability

Choose energy-efficient models for your cooking equipment set to lower your utility bills and support sustainability. Newer restaurant kitchen equipment can cut energy use by 20-50%. Look for ENERGY STAR or A+ ratings. These models often have better insulation, LED lighting, and precise temperature controls.

- Replace old equipment that uses too much power. Some appliances can make up over 30% of your energy bill.

- Electric equipment often has higher thermal efficiency than gas, saving you money over time.

- Durable equipment made from high-quality materials lasts longer and needs fewer repairs.

- Advanced features like smart scheduling and inventory management boost operational efficiency.

Selecting energy-efficient models not only reduces costs but also supports sustainability in kitchen equipment. You help the environment by lowering your carbon footprint and meeting local regulations. Many energy-efficient appliances come with warranties and external support, giving you peace of mind.

Consider Ease of Cleaning and Maintenance

Easy-to-clean restaurant kitchen equipment saves you time and money. Choose equipment with smooth surfaces and removable parts. Train your staff to use proper cleaning methods, like scrub brushes and approved cleaners, instead of just spraying water.

- Use the right cleaning tools and products to extend equipment life.

- Teach staff to perform regular maintenance tasks, such as descaling and changing filters.

- Set up a preventive maintenance schedule to replace worn parts before they fail.

- Keep repair and maintenance logs to track performance.

- Pick vendors with clear billing policies to avoid surprise costs.

- Train managers and staff to troubleshoot simple issues.

When you select equipment that is easy to clean and maintain, you control repair costs and keep your kitchen running smoothly. This approach also supports sustainability by reducing waste and extending the lifespan of your restaurant kitchen equipment. Focusing on sustainability in kitchen equipment helps you meet health standards and protect your investment.

Comparing Cooking Equipment Set Options

New vs. Used Equipment

When you choose restaurant kitchen equipment, you face a decision between new and used options. New equipment gives you the latest technology, energy efficiency, and full warranties. You can expect fewer repairs and longer lifespans. Used restaurant kitchen equipment often costs less upfront. This choice helps you save money if you have a tight budget. However, used items may need more maintenance and might not include a warranty. Always check the condition and service history before you buy used equipment. Consider your long-term needs and the total cost of ownership.

Key Features to Look For

You want restaurant kitchen equipment that boosts your kitchen’s performance. Focus on these features:

- Quality and durability: Strong equipment lasts longer and reduces downtime.

- Energy efficiency: Lower energy bills help your bottom line.

- Proper sizing: Equipment that fits your space improves workflow.

- Easy maintenance: Simple cleaning saves time and keeps your kitchen safe.

- Technological integration: Digital controls and remote monitoring increase consistency.

- Vendor reliability: Good support keeps your restaurant kitchen equipment running.

These features help you control costs and deliver consistent food quality. Many new models, like the iCombi Pro combi oven, use smart technology to improve speed and efficiency.

Evaluating Suppliers and Warranties

Choosing the right supplier for restaurant kitchen equipment matters. Reliable suppliers offer strong after-sales service, quick parts delivery, and clear warranty terms. Look for warranties that last 1-3 years and cover most repairs. Check if the supplier provides user training and technical support. Read customer reviews and ask about their experience with warranty claims. A good supplier helps you avoid downtime and protects your investment in restaurant kitchen equipment.

Tip: Always ask about parts availability and response times before you buy. Fast service keeps your kitchen running smoothly.

Tips for Maximizing Efficiency in Your Commercial Kitchen

Smart Kitchen Layout and Equipment Placement

You can boost your kitchen’s efficiency by planning a smart layout and placing equipment wisely. Define clear work zones for cooking, prep, storage, and cleaning. Place prep tables next to cooking stations to cut down on walking. Store your most-used tools and ingredients within arm’s reach using labeled bins and shelves. Modular and mobile equipment lets you adjust your setup as your needs change. Strategic placement based on how often you use each item helps you work faster and safer.

- Minimize cross-traffic to speed up service and reduce accidents

- Use ergonomic designs to lower staff fatigue

- Optimize space for better storage and movement

- Cut costs by reducing waste and saving energy

- Improve customer experience with faster service

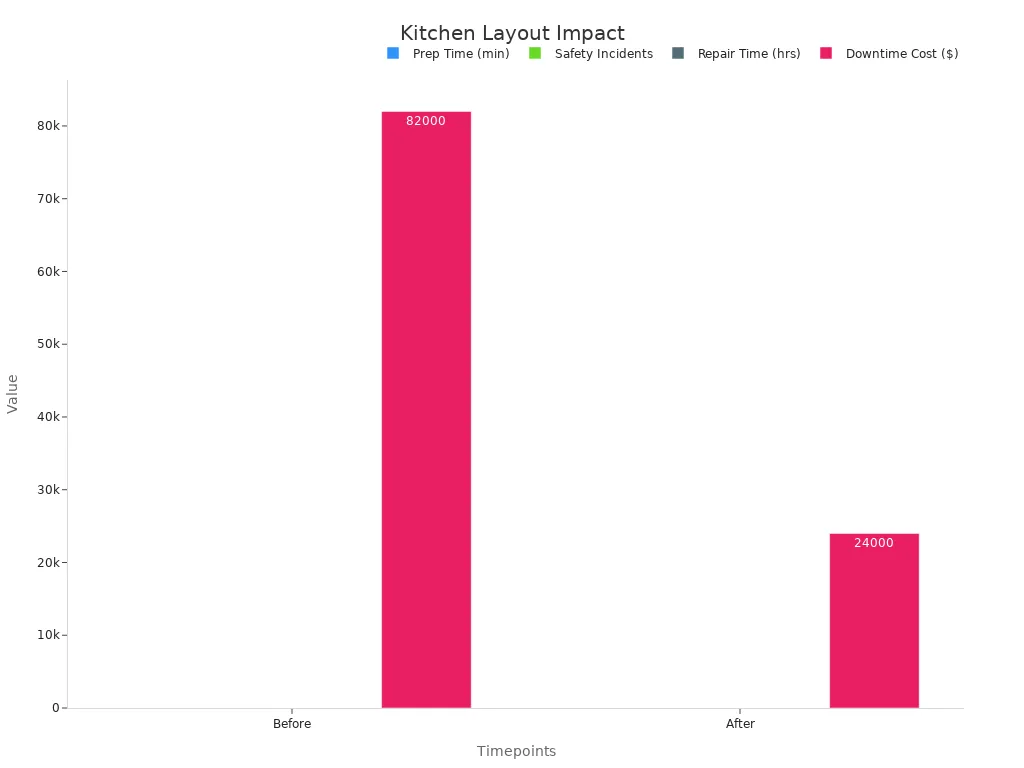

Smart layouts can reduce food prep time from 8.2 to 6.5 minutes and lower safety incidents each month. Equipment breakdowns drop by 40%, and downtime costs fall sharply.

Streamlining Workflow and Processes

You can streamline your workflow by setting clear goals and organizing tasks. Assign specific jobs to each station and use time-motion studies to spot slowdowns. Restaurants that set efficiency goals see a 12% average increase in productivity.

- Reduce order errors by up to 90%

- Decrease customer wait times by 20-30%

- Increase kitchen efficiency by 15-25%

- Use kitchen display systems to speed up orders

- Standardize recipes and monitor cooking times for consistency

Track key metrics like food prep time, service speed, and waste. These steps help you deliver better service and keep your kitchen running smoothly.

Staff Training and Best Practices

Train your staff on best practices to keep your kitchen efficient and safe. Teach them to prep ingredients before busy hours and organize their stations. Cross-train team members so they can help in different areas. Use kitchen display systems to cut down on mistakes.

| Performance Indicator | Benefit |

|---|---|

| Order Accuracy | Fewer mistakes and less waste |

| Preparation Time | Faster service and happier customers |

| Food Cost Percentage | Better inventory control and lower expenses |

| Labour Cost Percentage | Smarter staffing and cost savings |

| Customer Satisfaction | Higher quality and repeat business |

Encourage teamwork and regular feedback. Clean, organized workspaces and clear communication help everyone do their best.

Maintenance and Longevity of Essential Commercial Kitchen Cooking Equipment

Regular Cleaning and Care

You keep your kitchen running smoothly when you clean your equipment every day. Regular cleaning and lubrication reduce friction and wear, which helps your machines work better and last longer. For example, when you clean conveyor belts and high-capacity dishwashers, you prevent jams and keep production moving. Preventive maintenance, like daily wipe-downs and weekly deep cleans, lowers the risk of breakdowns and supports food safety. You also protect your investment by following a cleaning schedule for each piece of equipment.

Scheduled Inspections and Servicing

You should schedule inspections and professional servicing based on how often you use your equipment. This approach helps you catch small problems before they become big repairs. The table below shows how regular maintenance and inspections can extend the life of your kitchen tools:

| Equipment Type | Maintenance Practices | Typical Lifespan (Years) |

|---|---|---|

| Ovens and Stovetops | Cleaning, pilot checks, ventilation maintenance | 10 – 15 |

| Freezers | Cleaning, temperature control, timely repairs | 10 – 20 |

| High-capacity Dishwashers | Servicing and cleaning | 7 – 10 |

| Grills and Griddles | Scraping residue, inspections | 10 – 15 |

| Walk-In Coolers | System maintenance, insulation checks | 15 – 30 |

Tip: Scheduled maintenance can reduce your repair costs by up to 18% and deliver a return on investment as high as 400%. You also avoid unexpected downtime and keep your kitchen safe.

Extending Equipment Lifespan

You extend the lifespan of your equipment by combining regular cleaning, scheduled inspections, and prompt repairs. Preventive maintenance, such as calibrating ovens and checking refrigerator seals, keeps your machines working efficiently. For example, cleaning refrigerator coils can lower energy use and help compressors last longer. Quarterly servicing of fryers can add years to their life. When you keep maintenance logs and follow manufacturer guidelines, you avoid costly emergency repairs and keep your kitchen running. The importance of commercial freezers stands out because they protect your inventory and support food safety. Well-maintained equipment also keeps its value, which helps if you decide to upgrade in the future.

- Review your menu, kitchen space, and budget before you choose equipment.

- Match each tool to your workflow for better results.

- Invest in durable, energy-efficient models for long-term savings.

Quality equipment supports your business growth and keeps your kitchen running smoothly. Make smart choices for lasting success.

FAQ

What is the most important factor when choosing commercial kitchen equipment?

You should focus on your menu needs first. Select equipment that matches your food offerings and expected volume. This step ensures smooth kitchen operations.

Tip: Always check local health codes before purchasing.

How often should you service your commercial kitchen equipment?

You should schedule professional servicing every three to six months. Regular maintenance prevents breakdowns and extends equipment lifespan.

Can you mix new and used equipment in your kitchen?

Yes, you can mix both. Choose new equipment for critical tasks and use high-quality used items for less demanding roles. Always inspect used equipment before buying.