Commercial blenders for smoothies provide unmatched strength and reliability in busy settings.

- The global market for commercial blenders for smoothies reached $2.1 billion in 2023 and continues to grow fast.

- These commercial blenders for smoothies use powerful motors and advanced features to deliver smooth, consistent results in every smoothie shop.

A case study showed that using the best commercial blender, like the Vitamix Commercial 7500, helped one blender for smoothies cut serving time by 40%. Every commercial blender for smoothies blends tough ingredients quickly, making it the top blender for smoothies in any professional kitchen.

Best Commercial Blenders: Power, Performance, and Consistency

Handling Tough Ingredients and Large Volumes

Commercial blenders for smoothies stand out because they can handle tough ingredients and large batches with ease. Many smoothie shops use ingredients like frozen fruit, nuts, seeds, and ice. These items can slow down or damage weaker machines. The best commercial blender uses high-powered motors and strong blades to crush even the hardest foods. This power means faster blending and smoother results.

The table below shows how different power levels affect performance:

| Power Category (W) | Typical Use Case | Performance Characteristics |

|---|---|---|

| Below 500W | Light-duty tasks (smoothies, soft foods) | Limited power, less suitable for tough ingredients |

| 500W – 1000W | Versatile tasks (crushing ice, harder ingredients) | Balanced performance and affordability, suitable for wider range |

| Above 1000W | Heavy-duty commercial use | Handles toughest ingredients (nuts, seeds) with ease, high durability |

A high-capacity blender with more than 1000W can blend large volumes without losing speed or quality. For example, the Quick & Quiet commercial blender works 30% faster than The Quiet One®. It uses dual blade sets and a motor that keeps its speed, even with heavy loads. This design helps shops serve more customers in less time and keeps the texture smooth, even with dense ingredients.

Achieving Smooth, Uniform Blends Every Time

Smoothie-making capabilities depend on more than just power. The best commercial blenders use smart features to create uniform blends every time. These machines have heavy-duty motors and sharp blades that cut through ice, nuts, and frozen fruits. They also use smart sensors to detect what is inside the jar. The sensors adjust speed and time, so every batch comes out the same.

- Heavy-duty motors and blade assemblies blend tough ingredients thoroughly.

- Smart sensors adjust blending time and speed for consistent texture.

- Touch interfaces make operation easy and reduce staff training time.

- Jarless blending designs speed up cleaning and increase output.

- Variable speed controls and powerful blades adapt to different recipes.

- Connectivity and data logging help monitor blending cycles and maintenance.

- Noise reduction features make these blenders suitable for customer-facing areas.

- Dual-blade torque systems mix large batches quickly and evenly.

These features help smoothie shops deliver the same quality in every cup, even during busy hours. Staff can rely on the commercial blender to do the hard work, which reduces mistakes and keeps customers happy.

Meeting High-Demand, Continuous Use

Busy smoothie shops need equipment that can run all day without breaking down. Commercial blenders for smoothies are built for this kind of work. They use durable parts, noise reduction, and advanced controls to keep running smoothly. The demand for high-capacity, durable blenders is rising as more cafes and restaurants offer blended drinks.

High-capacity commercial blenders with jars above 2 liters are popular in large shops. These machines have strong motors and tough materials. They also use noise reduction technology, so staff can blend drinks without disturbing customers. The table below shows some key features:

| Aspect | Numerical Evidence | Explanation |

|---|---|---|

| Motor Power | 1.5 to 2.2 horsepower (HP) | Supports continuous operation by maintaining consistent speed during extended use. |

| Replacement Intervals | Every 3-6 months | Recommended for wear parts like rollers and blades to maintain optimal performance. |

| Capacity | 1.5L (smaller commercial) to 10L (industrial) | Larger capacities reduce bottlenecks in high-demand environments by minimizing refills. |

The best commercial blender can run for hours and blend hundreds of drinks each day. This reliability means less downtime and more sales. Shops save money because they do not need to replace parts as often. The performance of these machines supports the fast pace of modern smoothie businesses.

Commercial Blender Durability, Efficiency, and Cost-Effectiveness

Built to Last in Busy Environments

Smoothie shops and cafes need machines that can handle constant use. Commercial blenders use strong motors, thick blades, and sturdy jars. These parts resist wear and tear, even when blending tough ingredients like ice or frozen fruit. Many shops run their blenders for hours each day. The best models keep working without breaking down.

Manufacturers design these blenders for heavy-duty use. They use materials like stainless steel and reinforced plastics. These choices help the machines last longer. Shops that use commercial blenders see fewer breakdowns and less time spent on repairs. Staff can focus on serving customers instead of fixing equipment.

Tip: Regular cleaning and scheduled maintenance help extend the life of any blender. Shops that follow a maintenance plan get the most value from their investment.

Faster Blending and Higher Productivity

Speed matters in busy smoothie shops. Commercial blenders blend drinks faster than home models. They use powerful motors and sharp blades to crush ingredients quickly. This speed helps shops serve more customers in less time.

Studies show that increasing the speed of the blender’s impeller and the number of blade passes improves how well ingredients mix. When the blender runs faster, it creates smoother blends and better texture. Researchers found that there is a limit to how much speed helps. After a certain point, more speed does not make the blend better. Shops can find the best speed and fill level to get the fastest, highest-quality results.

Scientists also tested different ways to mix ingredients. They found that adding baffles or changing the direction of the blender’s rotation can make blending even faster. These changes help the blender mix everything evenly, so every smoothie tastes the same.

- Fast blending means shorter wait times for customers.

- Shops can serve more drinks each hour.

- Consistent blending improves product quality.

Long-Term Savings and Reduced Downtime

Investing in a durable blender saves money over time. Reliable machines break down less often, so shops spend less on repairs and replacements. Data shows that a 1% increase in blender reliability can bring in $2,800 more revenue each year for a busy shop. Most blender failures happen because of skipped maintenance. Shops that follow a maintenance schedule see 42% lower repair costs each year.

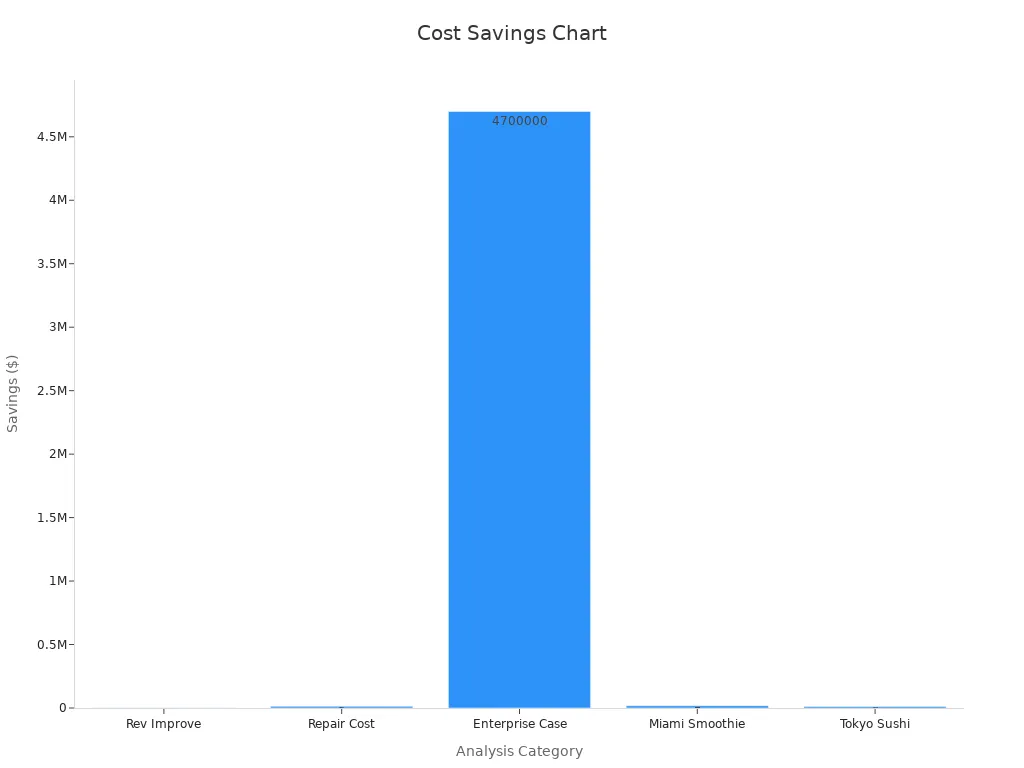

The table below shows how proper care and smart choices lead to big savings:

| Evidence Aspect | Details / Metrics |

|---|---|

| Revenue Improvement | 1% increase in blender reliability leads to $2,800 additional annual revenue per unit in high-volume settings. |

| Failure Causes | 68% of catastrophic blender failures due to neglected maintenance (motor carbon buildup 41%, seal degradation 27%). |

| Repair Cost Reduction | 42% decrease in annual repair costs (from $31,700 to $18,400) with structured maintenance protocols. |

| Mean Time Between Failures (MTBF) | 31% longer MTBF: 6,200 hours vs 4,730 hours without maintenance. |

| Enterprise Case (Starbucks) | 59% fewer blender replacements since 2020; $4.7M cumulative savings across 12,000+ locations; 83% technician compliance. |

| Case Study – Miami Smoothie Chain | Eliminated blender replacements for 2 years, reduced noise complaints by 92%, and cut energy use by 18%, saving $18,000 annually. |

| Case Study – Tokyo Sushi Chain | Restored a 1998 blender instead of buying a $12,000 replacement, achieving full functionality at a fraction of the cost. |

| Maintenance Practices | Scheduled thermal imaging, OEM replacement parts, and smart monitoring systems extended motor life from 3 to 7 years. |

Shops that use a commercial blender and follow a maintenance plan see fewer breakdowns and longer machine life. They also save on energy and reduce noise, making the work environment better for staff and customers.

The best commercial blender helps smoothie shops achieve professional-grade results. Industry data shows that investing in quality equipment increases preparation speed by 30% and boosts monthly revenue by $5,000. Smoothie businesses that choose commercial blenders see greater efficiency, consistent quality, and long-term savings.

FAQ

What makes a commercial blender different from a home blender?

A commercial blender uses a stronger motor and tougher parts. It blends faster and lasts longer in busy places like smoothie shops.

How often should a smoothie shop maintain its commercial blender?

Shops should clean and check their blenders every day. Regular maintenance helps prevent breakdowns and keeps the machine running well.

Are there different types of commercial blenders for smoothies?

Yes, shops can choose from several types of commercial blenders. Some work best for large batches, while others focus on quiet operation or speed.