You protect your investment in kitchen equipment by practicing preventive maintenance. You keep commercial kitchen appliances running smoothly with regular maintenance. Clean cook equipment each day to extend the life of your commercial kitchen appliances. When you spot issues early, you help extend the lifespan of commercial kitchen equipment and avoid expensive repairs to cooking equipment in your commercial kitchen.

Essential Maintenance to Extend the Lifespan of Commercial Cooking Equipment

Daily Cleaning and Surface Care for Cook Equipment

You keep your kitchen equipment in top shape by making daily cleaning a habit. When you clean cook equipment every day, you remove grease, food particles, and grime that can cause damage or lead to health code violations. Clean appliances after each use to prevent cross-contamination and maintain a safe environment. Wipe down surfaces to stop residue buildup, which can impair the function of commercial kitchen equipment.

Regular cleaning of kitchen exhaust systems reduces strain on motors and fans. This practice prevents corrosion and extends the lifespan of your commercial kitchen appliances. A well-maintained exhaust system uses less energy and breaks down less often. You help your staff focus on food preparation instead of emergency repairs, which boosts operational efficiency.

Tip: Use digital checklists or cleaning apps to track daily cleaning tasks. This ensures you complete all steps and maintain consistency.

Maintaining a clean kitchen also improves staff morale and customer satisfaction. You create a safe, efficient workspace that supports smooth operations and helps extend the life of your commercial kitchen appliances.

Weekly and Monthly Inspections of Commercial Kitchen Appliances

You protect your investment in commercial kitchen equipment by performing routine inspections. Weekly and monthly checks help you spot early signs of wear or malfunction. This allows you to schedule kitchen equipment repair before small issues become big problems.

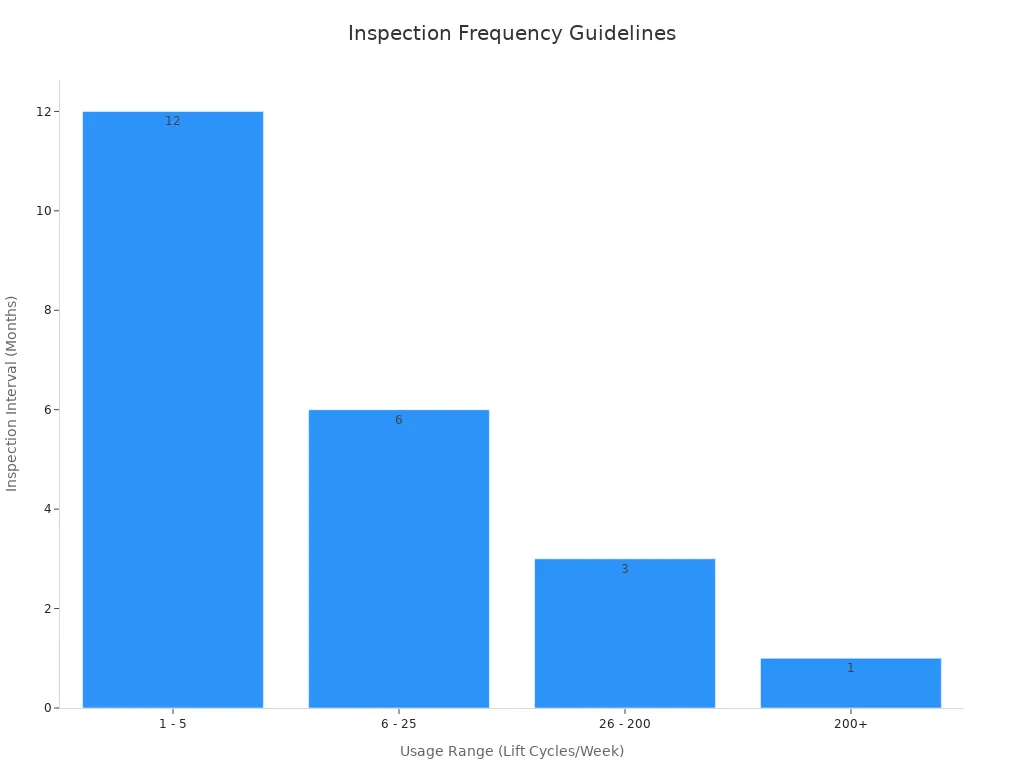

The frequency of inspections depends on how often you use your cooking equipment. The table below shows recommended inspection intervals based on usage:

| Usage Intensity (Lift Cycles per Week) | Recommended Inspection Frequency |

|---|---|

| 1 – 5 | 12 monthly |

| 6 – 25 | 6 monthly |

| 26 – 200 | 3 monthly |

| 200+ | Monthly |

You can use CMMS software to automate preventive maintenance schedules. This software sends reminders and tracks maintenance history, helping you catch problems early. Regular maintenance and inspections reduce the risk of equipment failure, lower repair costs, and help you extend the lifespan of your commercial kitchen appliances.

Proper Use, Handling, and Staff Training

You extend the life of your commercial kitchen appliances by training your staff in proper handling of the equipment. Teach your team to use kitchen equipment according to manufacturer guidelines. Show them how to spot early warning signs, such as strange noises or temperature changes. When staff report issues quickly, you can address them before they cause major damage.

Create standard operating procedures for cooking equipment care. Make sure everyone follows these steps every day. This reduces accidents and keeps your commercial kitchen appliances running smoothly. Staff who understand the right way to use and clean equipment help you avoid unnecessary wear and tear.

Note: Regular training sessions keep your team updated on best practices and new maintenance tips.

Choosing the Right Cleaning Products for Commercial Kitchen Equipment

You protect high-quality commercial kitchen equipment by using the right cleaning products. Harsh chemicals can damage surfaces and shorten the lifespan of kitchen equipment. Choose cleaners that match the material of your cook equipment, such as stainless steel or cast iron.

Always follow the manufacturer’s recommendations for cleaning products. Test new products on a small area first to avoid damage. Use soft cloths or brushes to prevent scratches. When you use the right products, you keep your cooking equipment looking new and working well.

Regular cleaning and maintenance with proper products help you extend the life of your commercial kitchen appliances. This approach supports preventive maintenance and keeps your kitchen equipment in top condition for years.

Spotting Early Wear and Taking Action to Protect Commercial Kitchen Equipment

Recognizing Early Warning Signs of Wear on Cook Equipment

You can prevent major breakdowns by learning to spot early warning signs on your kitchen equipment. Look for these common indicators:

- Unusual noises, such as grinding or rattling, during operation

- Inconsistent heating or temperature fluctuations

- Visible rust, corrosion, or cracks on surfaces

- Burnt smells or smoke during use

- Increased energy usage or higher utility bills

- Food quality changes, like uneven cooking or longer prep times

When you notice these signs, act quickly. Early detection allows you to schedule kitchen equipment repair before small problems become expensive failures. Regular maintenance checks help you catch these issues early. You keep your commercial kitchen appliances running smoothly and avoid unexpected downtime.

Tip: Keep a logbook or use a digital app to track any changes or issues with your kitchen equipment. This helps you spot patterns and address problems faster.

When to Repair or Replace Parts in Commercial Cooking Equipment

Deciding between repairing and replacing parts can save you money and keep your kitchen running efficiently. Use these criteria to guide your decision:

- Escalating repair costs signal that the equipment may be nearing the end of its useful life and replacement should be considered.

- Equipment inefficiency causing increased energy consumption and higher utility bills is a key factor favoring replacement.

- Diminished performance impacting food quality and operational consistency indicates the need for an upgrade.

- Safety concerns arising from malfunctioning parts or outdated technology necessitate immediate replacement.

- Difficulty or inability to source spare parts suggests obsolescence and supports replacement.

- Opportunities to consolidate multiple functions into a single, more efficient unit can justify replacement.

You should always prioritize safety and food quality. If you notice repeated breakdowns or rising costs for kitchen equipment repair, replacement may be the smarter choice. Timely repairs and servicing can extend the life of your commercial kitchen appliances, but sometimes upgrading is necessary for efficiency and safety.

Note: Preventive maintenance and regular inspections help you avoid premature replacement. Address issues early to keep your kitchen equipment in top condition.

Working with Professionals to Extend the Lifespan of Commercial Kitchen Appliances

Partnering with maintenance experts gives you a big advantage. Professional technicians use predictive maintenance programs to monitor your equipment and replace only worn parts. Research shows that these programs can extend equipment lifetime by up to 20%. You also benefit from fewer breakdowns and lower maintenance costs.

Here is how expert collaboration helps different industries:

| Industry Sector | Success Metrics / Outcomes |

|---|---|

| Manufacturing | 25-30% reduction in maintenance costs |

| 70-75% decrease in equipment breakdowns | |

| 35-45% reduction in downtime | |

| Energy & Utilities | 38% reduction in unplanned outages |

| 20% extension in equipment lifespan | |

| Transportation & Aviation | 16% reduction in maintenance-related delays |

| $7-9 million annual savings in maintenance costs | |

| 3.4% improvement in fleet availability |

You can see that working with professionals leads to fewer failures and longer-lasting equipment. Predictive maintenance reduces downtime by up to 30%. Companies that invest in staff training and expert support also see higher employee retention and better performance. Regular repairing and servicing by professionals ensures your kitchen equipment stays reliable and efficient.

Callout: Use IoT sensors and real-time monitoring tools to catch problems early. This technology helps you prevent costly breakdowns and keeps your commercial kitchen appliances operating at their best.

By choosing expert support and advanced maintenance strategies, you protect your investment and keep your kitchen running smoothly for years.

You protect your kitchen equipment by making maintenance a daily habit. Nearly 80% of managers use preventive maintenance, which increases uptime by up to 20% and extends asset life by 40%.

| Statistic Description | Value/Percentage |

|---|---|

| Maintenance managers using preventive maintenance (2024) | Nearly 80% |

| Increase in asset uptime from predictive maintenance (PdM) | 10% to 20% |

| Extension of asset lifespan via continuous monitoring | 20% to 40% |

| Plants experiencing unexpected downtime monthly | Almost 70% |

You save money and avoid costly repairs by following a regular maintenance schedule for kitchen equipment. Proactive care delivers these benefits:

- 545% ROI from proactive HVAC maintenance

- 30% longer equipment life with scheduled maintenance

- 25-40% lower energy costs from efficient kitchen equipment

Train your staff, use the right products, and make maintenance a priority. You keep your kitchen equipment running longer and protect your investment.

FAQ

How often should you clean commercial cook equipment?

You should clean your equipment daily. This habit removes grease and food particles. Daily cleaning helps prevent damage and keeps your kitchen safe.

What signs show your kitchen equipment needs repair?

Listen for strange noises. Watch for uneven heating or visible rust. If you see these signs, schedule a repair soon.

Can you use household cleaners on commercial kitchen appliances?

No, you should not use household cleaners. Always choose products made for commercial equipment. These products protect surfaces and prevent early wear.