Choosing the best nonstick frying pan means understanding what causes most nonstick surfaces to fail. According to consumer studies, common mistakes can shorten the life of even the best nonstick frying pans:

| Common Reason for Failure | Explanation and Impact |

|---|---|

| Use of metal utensils | Scrapes coating, leads to sticking and safety concerns |

| Stacking pans without protection | Scratches surface, speeds up coating damage |

| Overheating empty pans | Damages nonstick, shortens pan life |

Home cooks who select top-rated nonstick models and care for them properly enjoy longer-lasting cooking results. The best overall nonstick frying pan resists damage and keeps food sliding smoothly, making nonstick cooking easy and safe.

What Makes the Best Nonstick Frying Pan Durable?

Coating Strength and Composition

The strength and composition of the coating play a major role in nonstick durability. Manufacturers use different materials to create coatings that resist wear and keep food from sticking. Consumer Reports tested nonstick frying pans by rubbing them with steel wool thousands of times. Pans with ceramic coatings, such as those from Caraway and GreenPan, showed very good durability. The Swiss Diamond HD Nonstick pan, which uses a high-quality PTFE-based coating, also performed well. Both ceramic and traditional PTFE coatings help maintain nonstick properties after heavy use. These results show that the best heavy-duty nonstick frying pan uses advanced coating materials to improve nonstick coating durability.

- Ceramic coatings (PTFE-free) and high-quality PTFE coatings both enhance durability.

- Nonstick frying pans with these coatings resist abrasion and keep their nonstick surface longer.

Pan Construction and Materials

The material and construction of a nonstick frying pan affect its performance and lifespan. Most nonstick frying pans use aluminum, stainless steel, or hard anodized aluminum. Aluminum offers excellent heat conductivity and keeps the pan lightweight. Stainless steel adds strength and resists rust. Some pans use multi-ply construction, layering aluminum between stainless steel. This design improves heat distribution and prevents warping. Multi-ply pans last longer and protect the nonstick coating from damage caused by uneven heating.

| Metal Type | Key Properties & Usage in Nonstick Pans |

|---|---|

| Aluminum | Excellent heat conductivity, lightweight, can be anodized or coated with nonstick surfaces. |

| Stainless Steel | Durable, nonreactive, often bonded with aluminum for better heat conduction. |

| Carbon Steel | Less common, heavy, needs seasoning, reactive to acids. |

| Cast Iron | Rare for nonstick pans, heavy, needs maintenance. |

| Copper | Great heat conductor, less common, usually lined with stainless steel or tin. |

Resistance to Scratching and Peeling

A nonstick frying pan must resist scratching and peeling to stay effective. Manufacturers design coatings to withstand daily use, but even the best heavy-duty nonstick frying pan can wear out over time. According to America’s Test Kitchen, high-quality nonstick frying pans last about six months with heavy use. With careful handling, they can last up to one and a half years before significant peeling occurs. Using gentle utensils and avoiding high heat helps preserve the nonstick coating. These habits extend the life of the nonstick frying pan and keep its nonstick properties strong.

Tip: Always use wooden or silicone utensils to protect the nonstick coating and increase durability.

Comparing the Best Nonstick Frying Pan Technologies

PTFE (Teflon) Nonstick Coatings

PTFE, often called Teflon, remains the most common nonstick technology in kitchens. Independent tests, including the AFNOR NF D 21-511 “milk test” and “egg test,” show that PTFE coatings outperform other types in both durability and nonstick food release. These tests use tools like rotating brass brushes and abrasion machines to simulate years of use. PTFE coatings keep their nonstick properties even after mechanical damage, while ceramic coatings lose effectiveness more quickly. PTFE also resists high temperatures and provides smooth food release for eggs, pancakes, and delicate foods.

However, PTFE coatings raise health and safety concerns. Chemicals used in PTFE production, such as PFOA and Gen X, belong to a group called PFAS or “forever chemicals.” These chemicals do not break down easily in the environment. Health risks linked to PFAS include cancer, changes in liver enzymes, and pregnancy complications. PTFE fumes released at high heat can harm humans and are especially dangerous to birds.

Note: PTFE nonstick pans should never be heated above 500°F (260°C). Overheating can release toxic fumes.

- Heating PTFE above 570°F (300°C) causes it to break down and release fumes.

- Inhaling these fumes can cause flu-like symptoms in humans.

- PTFE fumes are deadly to birds.

- PTFE particles that flake off are not harmful if swallowed, but fumes and chemicals used in manufacturing pose risks.

- Environmental concerns remain due to PFAS contamination.

Ceramic Nonstick Frying Pan Surfaces

Ceramic nonstick coatings offer an alternative to PTFE. Manufacturers make these coatings from natural materials like beach sand, and they do not contain PTFE, PFOA, or PFAS. Ceramic pans do not release toxic fumes, even at high temperatures, making them safer for high-heat cooking. However, ceramic coatings are more brittle and prone to microscopic cracks. This brittleness leads to a shorter lifespan and reduced nonstick food release over time.

| Aspect | Ceramic Nonstick Pans | PTFE (Teflon) Nonstick Pans |

|---|---|---|

| Coating | Made from natural materials, no PTFE/PFOA/PFAS | Synthetic polymer coating containing PTFE |

| High-Temp Safety | No toxic fumes at high temperatures | Should not be used above 500°F due to fume risk |

| Durability | More brittle, shorter lifespan | More durable, but breaks down at high heat |

| Recommended Use | Low to medium heat | Low to medium heat |

| Cost | Generally more expensive | Generally less expensive |

Most ceramic-coated pans last between 1 to 3 years with normal use. High-quality ceramic nonstick coating can last longer, especially with gentle cleaning and proper utensils. Frequent high-heat cooking, metal utensils, and abrasive cleaning shorten the lifespan. Experts recommend replacing ceramic pans when the coating shows scratches, chips, or loss of nonstick food release.

Hard-Anodized Nonstick Frying Pans

Hard-anodized frying pans use a special process to make aluminum harder and more durable. The anodization process creates a thick, stable aluminum oxide layer on the pan. This layer makes the surface resistant to scratches, dents, and corrosion. Hard-anodized pans do not rust and can handle high heat without warping. The tough surface protects the pan from damage, even with regular use.

- Hard-anodized aluminum has an exceptionally tough surface.

- The anodized layer resists scratches, chipping, and peeling.

- The pan withstands high heat and does not warp easily.

- The oxide layer protects against corrosion and rust.

- The surface is naturally stick-resistant, but not as slick as coated nonstick pans.

The anodized surface offers moderate nonstick properties, but it does not match the easy food release of PTFE or ceramic coatings. Hard-anodized pans last longer than most coated nonstick frying pans, especially when users avoid harsh cleaning and use proper utensils.

Diamond, Titanium, and Mineral-Infused Nonstick Coatings

Manufacturers have developed new nonstick technologies by adding diamond, titanium, or minerals to the coating. Diamond cookware uses tiny diamond particles infused into ceramic coatings or bonded to the pan surface. This process creates a strong bond, making the coating scratch-resistant and durable. Diamond coatings offer natural nonstick properties and resist chemicals and water.

- Diamond coatings use vacuum brazing to attach diamond particles, increasing durability.

- Diamond-reinforced pans last up to five times longer than entry-level pans.

- Titanium is added to PTFE or ceramic coatings for slight durability improvements, but the lifespan is similar to traditional coatings.

- Titanium nanobond coatings, like Hestan NanoBond, are very durable and withstand high heat, but they are not truly nonstick.

- Mineral-infused coatings, such as those with plant-based oils, require reseasoning and do not significantly extend lifespan compared to traditional coatings.

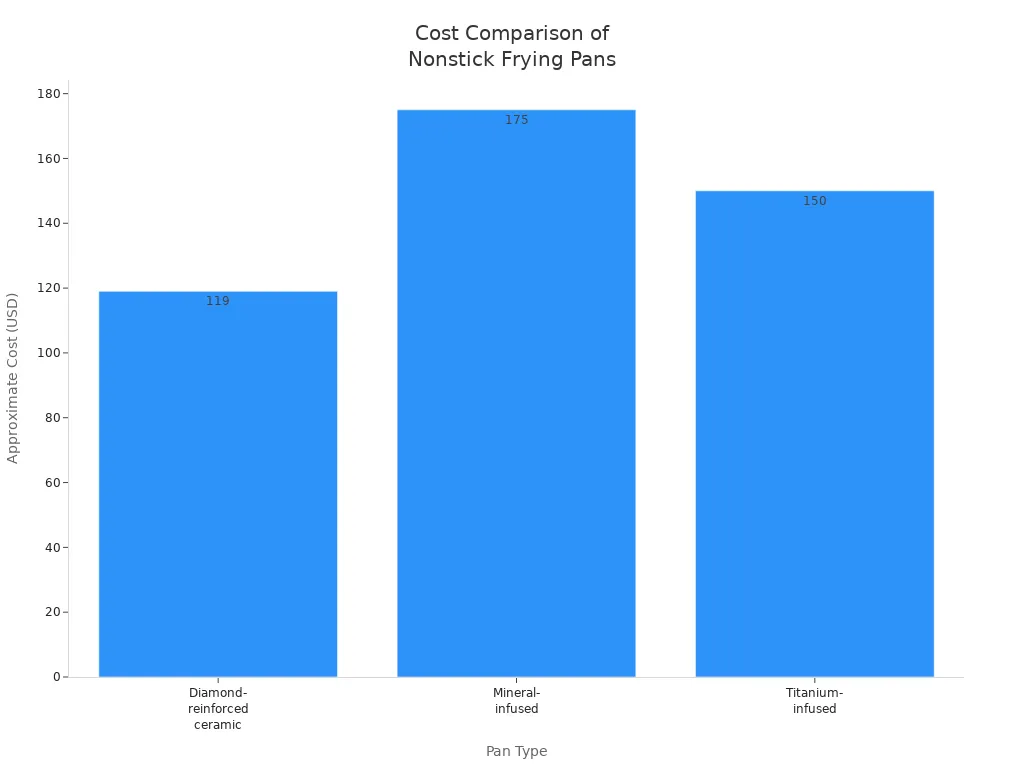

The cost of these advanced pans varies. Diamond-reinforced ceramic pans, such as the Alva Maestro, cost around $119 and come with a 10-year warranty. Mineral-infused pans, like the Alva Forest, cost about $175 and need regular reseasoning. Titanium-infused pans, such as the Titanium Always Pan Pro, cost about $150 and feature a titanium interior that is 300% harder than stainless steel. This pan can withstand temperatures up to 1000°F and is nearly indestructible.

Proper care, such as gentle cleaning and avoiding overheating, extends the lifespan of all these pans. Diamond and mineral-infused pans rely on durable coatings, while titanium-infused pans offer a robust, coating-free construction for the longest lifespan.

Key Innovations in Best Nonstick Frying Pan Longevity

Multi-Layer Nonstick Systems

Multi-layer nonstick systems have changed how frying pans perform in the kitchen. Manufacturers now use nanotechnology to create coatings that resist wear and handle temperatures up to 550°F. Sol-gel coatings bond tightly to the pan, improving both nonstick durability and heat resistance. Some brands add graphene to the layers, which increases abrasion resistance and even adds antibacterial properties. Eco-friendly, PFOA-free ceramic coatings have become popular, addressing health and environmental concerns. These multi-layer coatings, when combined with hard-anodized aluminum or stainless steel bases, boost both nonstick performance and longevity. Diamond-infused and titanium-reinforced surfaces also extend the lifespan of nonstick pans, lasting up to three times longer in stress tests. Smart cookware features, such as embedded sensors and induction compatibility, are now common in new nonstick frying pans.

- Nanotechnology enhances wear resistance and temperature tolerance.

- Sol-gel and graphene layers improve bonding and antibacterial properties.

- Diamond and titanium reinforcements increase nonstick durability.

- Eco-friendly coatings and smart features support modern kitchens.

Reinforced and Infused Nonstick Coatings

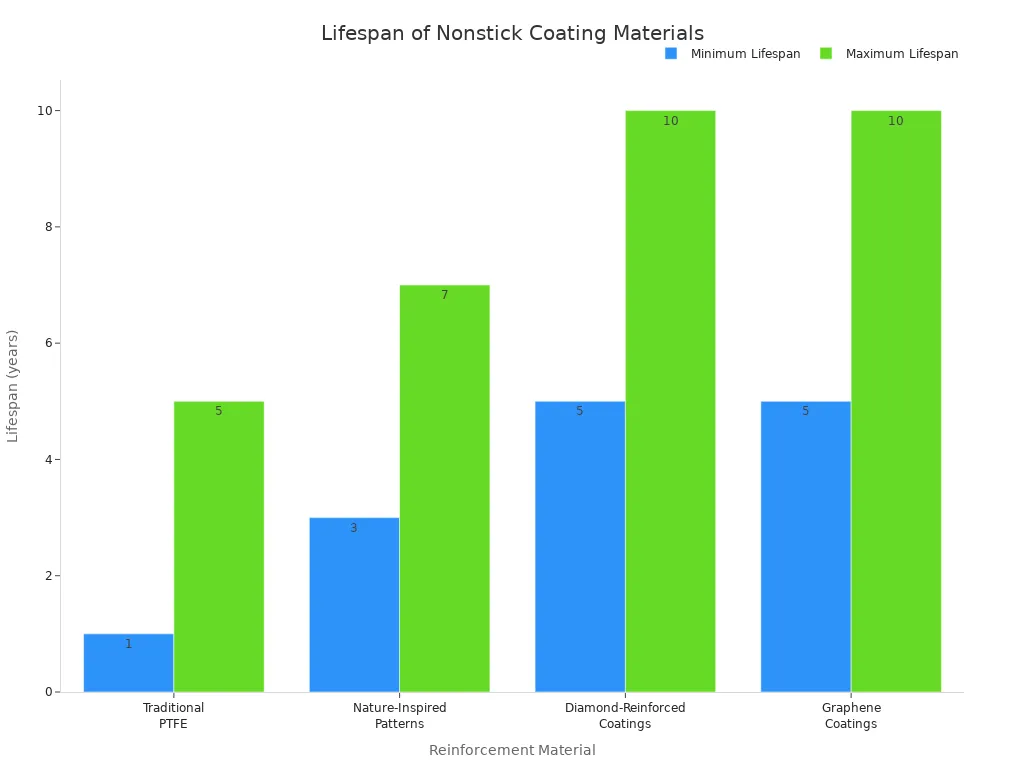

Reinforcement materials play a big role in extending the life of nonstick frying pans. Diamond-reinforced coatings use tiny diamond particles to make the surface tough and scratch-resistant. Graphene coatings add strength and keep the pan lightweight. Nature-inspired surface patterns also help reduce scratches and wear. These innovations improve nonstick durability and keep food from sticking for years.

| Reinforcement Material | Scratch Resistance | Non-Stick Performance | Lifespan (years) |

|---|---|---|---|

| Traditional PTFE | Moderate | Good | 1-5 |

| Nature-Inspired Patterns | High | Excellent | 3-7 |

| Diamond-Reinforced | Very High | Excellent | 5-10 |

| Graphene | High | Excellent | 5+ |

Improved Bonding Techniques

Modern bonding techniques have made nonstick frying pans stronger and more reliable. Brands like All-Clad use tri-ply construction, which bonds layers of metal from the base to the rim. This method creates a tough, scratch-resistant surface and improves nonstick durability by up to 30%. Advanced layering and curing processes help fluoropolymer coatings, such as PTFE, stick better to the pan. These techniques lower the force needed to release food and increase abrasion resistance. Ceramic coatings still need improvement in bonding, but fluoropolymer coatings now last longer and perform better because of these new methods.

Tip: Pans with improved bonding techniques often last longer, even with daily use.

How to Choose the Best Overall Nonstick Frying Pan

Assessing Nonstick Coating Type and Thickness

Shoppers often compare the best nonstick frying pan options by looking at coating type and thickness. The coating must meet food safety standards, with a thickness of at least 25μm for durability. Manufacturers use professional gauges to measure this. Multi-layer coatings, such as resin bases with PTFE or mineral powder surfaces, improve resistance to peeling and boost nonstick effectiveness. The table below shows important criteria for evaluating coating quality and value:

| Criterion | Description |

|---|---|

| Coating Thickness Standard | Must meet national food safety standards; thickness ≥ 25μm for durability and resistance. |

| Measurement Method | Professional dry mil paint thickness gauge ensures compliance. |

| Coating Material Types | PTFE, ceramic, silicone; each affects nonstick performance and safety. |

| Coating Structure | Multi-layer structures improve peeling resistance and nonstick value. |

| Health and Safety | Thickness impacts migration of substances, affecting safety. |

| Durability Factors | Proper application and thickness increase longevity and value. |

Evaluating Pan Construction and Weight

The best overall nonstick frying pan features sturdy construction and balanced weight. Aluminum and stainless steel bases offer quality heat distribution and prevent warping. Hard-anodized aluminum increases scratch resistance and lifespan. A pan with a comfortable handle and moderate weight provides better control during cooking. Heavier pans often last longer, but lighter pans suit quick tasks and deliver best value nonstick frying pan performance.

Tip: Choose a pan with a solid base and ergonomic handle for both quality and value.

Safety and Non-Toxicity Considerations

Safety remains a top priority when selecting the best overall nonstick frying pan. Buyers should look for certifications such as FDA approval, NSF certification, and EU REACH compliance. These standards verify chemical safety and migration limits. Many brands highlight lead- and cadmium-free labels, PFAS-, PFOA-, and PTFE-free coatings, and third-party lab testing. The table below lists major certifications and standards:

| Certification/Standard | Region | Focus Areas | Regulatory Body |

|---|---|---|---|

| FDA | USA | Chemical safety, migration limits | U.S. Food and Drug Administration |

| NSF Certification | North America | Adhesion, thermal stability | NSF International |

| EU REACH | European Union | Chemical restrictions, PFOA ban | European Chemicals Agency |

| EN 12983-1 | Europe | Cookware performance, heat resistance | European Committee for Standardization |

| LFGB | Germany | Toxicity tests, food contact safety | German Federal Institute for Risk Assessment |

| JIS | Japan | Heat resistance, durability, safety | Japan Standards Association |

| GB 4806.10-2016 | China | Coating migration, toxicity | China National Food Safety Standards |

Consumers should also check for Prop 65 compliance and independent lab results to ensure the best value nonstick frying pan meets strict safety standards.

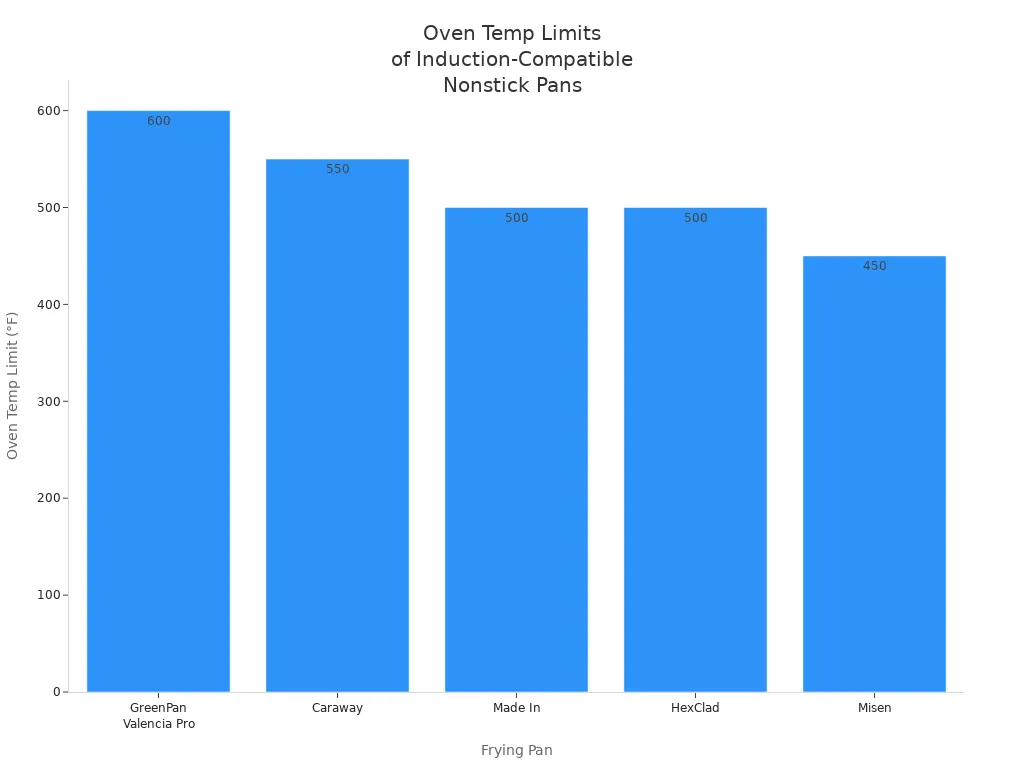

Compatibility with Cooktops and Ovens

The best overall nonstick frying pan must work with various cooktops and withstand oven heat. Induction-compatible pans use magnetic steel bases or embedded particles. For example, GreenPan Valencia Pro and Caraway pans support induction and resist oven temperatures up to 600°F and 550°F, respectively. Made In and HexClad pans also offer induction compatibility and handle up to 500°F. The chart below compares oven temperature limits for popular induction-compatible nonstick frying pans:

A buyer should always check manufacturer instructions for oven safety. The best splurge nonstick frying pan often features higher temperature limits and advanced compatibility, while the best value nonstick frying pan balances performance and price.

Tips for Maximizing Nonstick Frying Pan Performance

Proper Cleaning and Maintenance

Manufacturers recommend several steps to keep a nonstick frying pan easy to clean and long-lasting. Users should let the pan cool before washing. Hand washing with mild soap and a soft sponge removes residue without harming the coating. For stubborn food, a paste of baking soda or a mixture of vinegar and lemon works well. Dishwashers can cause discoloration and peeling, so hand washing is best. Drying the pan with a soft towel prevents water spots. Storing pans by hanging or using pan protectors between stacked pans helps avoid scratches. Using wooden, silicone, or nylon utensils keeps the surface smooth and easy to clean.

Tip: Never plunge a hot pan into cold water. This prevents thermal shock and warping.

Cooking Practices to Avoid Damage

Certain cooking habits help maintain the nonstick surface. Metal utensils scratch and chip the coating, so cooks should use wooden or silicone tools. High heat above 250°C breaks down the coating quickly. Heating an empty pan or cooking over high heat for long periods causes severe damage. Abrasive cleaning pads and harsh detergents also weaken the nonstick layer. Transferring food to a cutting board before slicing protects the pan. Avoiding knives and sharp objects on the surface keeps the pan easy to clean and safe for cooking.

When to Replace Your Nonstick Frying Pan

Signs that a nonstick frying pan needs replacement include visible chips, scratches, or flaking. Food sticking more often or unevenly means the nonstick properties have faded. Deep scratches that expose the base metal can release harmful particles. Discoloration, warping, or persistent odors signal the end of the pan’s useful life. Most pans last three to five years. Replacing the pan ensures safe and easy to clean cooking.

The best nonstick frying pan uses advanced coatings and strong construction for lasting performance. Proper care, such as gentle cleaning and correct utensils, adds value by extending lifespan from 2-3 years to 5-7 years. Choosing quality pans and following care tips gives the best value and long-term cooking value.

FAQ

How long does a nonstick frying pan usually last?

Most nonstick frying pans last three to five years. Proper care, such as gentle cleaning and using soft utensils, helps extend their lifespan.

Can nonstick frying pans go in the dishwasher?

Manufacturers often recommend hand washing. Dishwashers can damage the coating and shorten the pan’s life. Always check the care instructions for each pan.

Are nonstick frying pans safe for high-heat cooking?

Nonstick frying pans work best at low to medium heat. High heat can damage the coating and release harmful fumes. Use stainless steel or cast iron for high-heat cooking.

Tip: Always preheat nonstick pans on low or medium settings for best results.